Demister pads ensure safe, clean industrial operations. These simple yet brilliant devices take out the fine droplets of liquid from the gas stream, thus protecting the equipment, enhancing product quality, and also making sure that environmental norms are adhered to. Moving from chemical processing to oil and gas and pharmaceutical industries, demister pads can barely be absent from any system. This blog discusses in simple terms how demister pads operate, their types, applications, benefits, and how to pick the ones best suited for a particular need.

What Are Demister Pads?

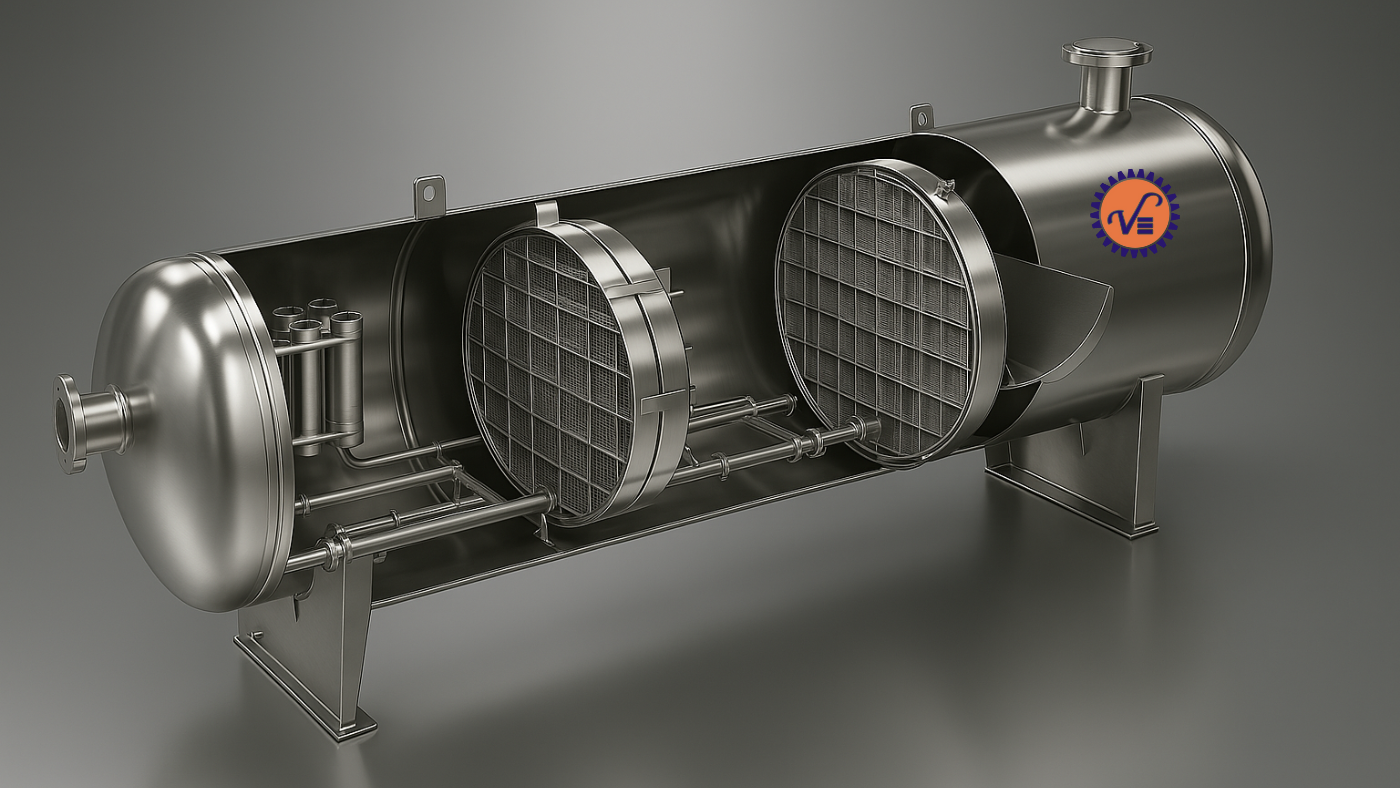

The basis of dropping some liquid droplets into a gas stream might just have been a quest for further evolution. Demister pads or mist eliminators, or vapour pads, are separators that remove liquid droplets from a gas or vapour stream. The size of these droplets can be a few microns, and sometimes they can become very dangerous as they can cause corrosion to the equipment, contaminate the product, or even pollute the environment. These demister pads capture the very fine aerosol-like droplets and let only the clean gas pass through.

Typically made from knitted wire mesh or structured plates, demister pads are made of stainless steel, plastic, or a special alloy, depending on the requirement. They are mostly installed on top of equipment such as distillation columns, scrubbers, or separators, thus drying the gas to ensure exit from the system. The idea behind their use is to improve the quality of the gas stream, protect the equipment downstream, and keep the subsequent processes working.

How Do Demister Pads Work?

Demister pads have a very simple but effective working mechanism, wherein the basis is on coalescence. Here is what happens step by step to create the effect of gas-liquid separation:

- Gas Enters the Pad: A gas stream carrying tiny liquid droplets flows into the demister pad, usually located at the top of a separator or column.

- Droplets Collide with the Mesh: As the gas moves through the pad’s mesh or plates, the liquid droplets, due to their inertia, can’t navigate the tight, winding paths. They collide with the wires or plates.

- Droplets Merge: These collisions cause the droplets to stick to the mesh or plate surfaces. Over time, smaller droplets combine to form larger ones through coalescence.

- Gravity Takes Over: Once the droplets grow large enough, their weight overcomes the upward force of the gas and surface tension. They slide down the pad to a collection area below.

- Clean Gas Exits: The gas, now free of liquid droplets, passes through the pad and continues to the next stage of the process.

Think of a demister pad like a coffee filter. The filter traps coffee grounds while letting the liquid pass through. Similarly, demister pads capture liquid droplets, allowing only clean gas to move forward. This process ensures high separation efficiency, often reaching up to 99.9%, with minimal resistance to gas flow.

Key Mechanisms in Gas-Liquid Separation

Demister pads rely on three main mechanisms to separate liquid droplets from gas streams:

- Inertial Impaction: Larger droplets, carried by the gas, have enough momentum to collide with the pad’s wires or plates. These collisions trap the droplets, preventing them from moving further.

- Direct Interception: Smaller droplets, following the gas flow, get caught when they brush against the mesh or plate surfaces. Even if they don’t collide head-on, they stick to the pad.

- Diffusion (Brownian Motion): Very tiny droplets move randomly due to molecular motion. This zigzag movement increases their chances of hitting and sticking to the pad’s surfaces.

These mechanisms work together to capture droplets as small as 3 to 5 microns, ensuring clean gas output. The pad’s design, including mesh density and wire diameter, is tailored to maximise these effects based on the droplet size and gas flow conditions.

Types of Demister Pads

Demister pads come in different types, each suited for specific applications. The two main types are:

1. Wire Mesh Demister Pads

Wire mesh demister pads are made of tightly woven metal or plastic wires, forming a dense, porous structure. They are ideal for capturing fine droplets, typically smaller than 10 microns. These pads are lightweight, cost-effective, and easy to install, making them popular for general-purpose applications like distillation columns and scrubbers. However, they may struggle with high gas velocities or heavy liquid loads, where re-entrainment of droplets can occur.

2. Vane-Type Demister Pads

Vane-type demister pads consist of parallel plates or vanes arranged to create a zigzag path for the gas. They are better suited for high gas velocities, larger droplet sizes (above 10 microns), and heavy liquid loads. Vane pads have a lower pressure drop and are easier to clean, making them ideal for dirty or fouling-prone environments like oil and gas separators.

Other Variations

- Standard Type: Used for general applications with moderate flow rates and droplet sizes.

- Efficient Type: Designed for finer droplet capture, offering higher separation efficiency.

- High Penetration Type: Built for heavy-duty applications with large liquid volumes or high gas velocities.

- Shock Absorber Type: Used in systems with fluctuating flow rates to prevent flooding.

Choosing the right type depends on factors like droplet size, gas velocity, liquid load, and operating conditions. Consulting with experts ensures the best fit for specific needs.

Applications of Demister Pads in Gas-Liquid Separation

Demister pads are used across various industries to ensure clean gas-liquid separation. Here are some key applications:

1. Chemical Industry

In chemical plants, demister pads are essential in distillation columns and scrubbers. They prevent liquid droplets from entering condensers or polluting gas streams. For example, in sulfuric acid production, demister pads remove acidic mists, protecting equipment and ensuring compliance with environmental regulations.

2. Oil and Gas Industry

Separators and scrubbers in oil refineries rely on demister pads to remove oil or water droplets from natural gas streams. This prevents corrosion in pipelines and ensures high-quality gas for downstream processes.

3. Pharmaceuticals

In pharmaceutical manufacturing, demister pads purify gases used in reactors, ensuring clean production environments. They help maintain product purity by removing liquid contaminants.

4. Power Generation

Steam turbines and boilers use demister pads to dry steam, protecting turbine blades from erosion and improving efficiency. They also control moisture in wastewater treatment systems.

5. Food and Beverage Industry

Evaporators in food processing use demister pads to concentrate liquids like juices or dairy products without losing quality. They prevent liquid carryover, ensuring pure vapour output.

6. Environmental Protection

Demister pads help scrub pollutants from exhaust gases, reducing emissions in industries like petrochemicals and power generation. They ensure compliance with strict environmental standards.

Benefits of Using Demister Pads

Demister pads offer numerous advantages that make them indispensable in gas-liquid separation:

- High Separation Efficiency: Capable of removing up to 99.9% of liquid droplets, ensuring clean gas output.

- Equipment Protection: Prevents corrosion, erosion, or fouling in downstream equipment like compressors and turbines.

- Environmental Compliance: Reduces emissions of mists and aerosols, helping industries meet regulatory standards.

- Process Optimisation: Improves heat transfer rates, maintains product quality, and enhances overall efficiency.

- Cost Savings: Reduces maintenance costs, extends equipment lifespan, and minimises downtime.

- Low Pressure Drop: Allows gas to flow with minimal resistance, saving energy.

- Easy Installation and Maintenance: Lightweight and simple to install, with minimal upkeep required.

- Durability: Made from corrosion-resistant materials like stainless steel or PTFE, ensuring long service life.

These benefits make demister pads a cost-effective solution for industries aiming to improve performance and sustainability.

Installation and Maintenance Tips

To maximise the performance of demister pads, proper installation and maintenance are essential:

Installation

- Tight Fit: Ensure the pad fits snugly against the vessel walls to prevent gas leaks.

- Correct Orientation: Install horizontally or vertically based on the vessel’s design and flow direction.

- Support Grids: Use grids or bars to hold the pad securely, especially in large vessels.

- Manhole Access: Choose upload or download installation based on the manhole’s location for easy access.

Maintenance

- Regular Cleaning: Over time, particles in the gas stream can clog the pad, increasing pressure drop and reducing efficiency. Clean with water, dilute solvents, or soaking to remove debris.

- Inspection: Check for damage or corrosion after cleaning. Measure wire diameter to ensure no degradation.

- Avoid Harsh Chemicals: Acidic cleaners can shorten the pad’s lifespan. Use neutral or mild solutions.

- Scheduled Maintenance: Regular checks prevent flooding and maintain separation efficiency.

Proper maintenance extends the pad’s life and ensures consistent performance in gas-liquid separation.

Choosing the Right Demister Pad

Selecting the right demister pad requires careful consideration of process needs. Here are tips to guide the decision:

- Assess Droplet Size: Use mesh pads for fine mists and vane pads for larger droplets.

- Evaluate Liquid Load: High liquid volumes need vane pads, while mesh pads suit lighter loads.

- Check Operating Conditions: Ensure materials can withstand temperature, pressure, and chemical exposure.

- Consider Space Constraints: Custom pads can fit unique vessel shapes or sizes.

- Prioritise Efficiency: Choose pads with high separation efficiency (e.g., 99% or more) for critical applications.

- Consult Experts: Work with manufacturers to design pads tailored to specific requirements.

Partnering with a reliable supplier ensures access to high-quality, customised solutions that meet industry standards.

The Future of Demister Pads

Advancements in materials and design are making demister pads even more effective. Innovations include:

- Advanced Materials: New alloys and polymers improve corrosion resistance and durability.

- Custom Designs: 3D modelling and computational fluid dynamics (CFD) allow for precise, application-specific pads.

- Hybrid Systems: Combining mesh and vane padsoptimisess separation for complex processes.

- Sustainability: Eco-friendly materials and designs reduce environmental impact.

These advancements ensure demister pads remain a cornerstone of gas-liquid separation in evolving industries.

Varun Engineering: Your Trusted Partner for Demister Pads

For industries seeking reliable, high-quality demister pads, Varun Engineering offers tailored solutions to meet unique needs. With a focus on precision, durability, and efficiency, Varun Engineering designs pads that enhance gas-liquid separation, protect equipment, and ensure compliance. Whether for chemical plants, oil refineries, or power generation, Varun Engineering delivers customised, high-performance demister pads for seamless operations.