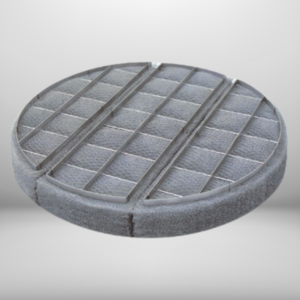

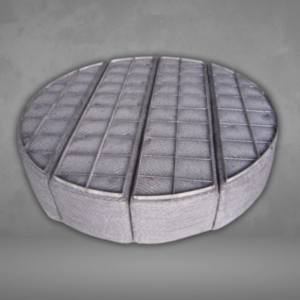

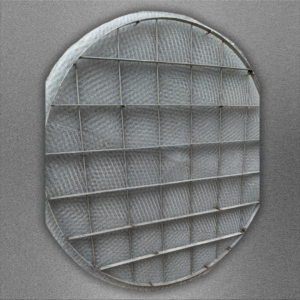

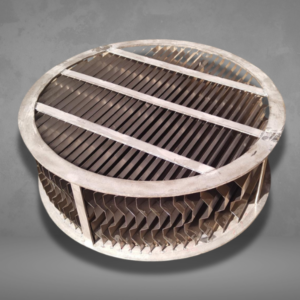

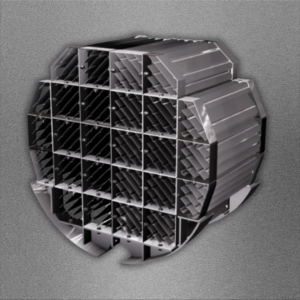

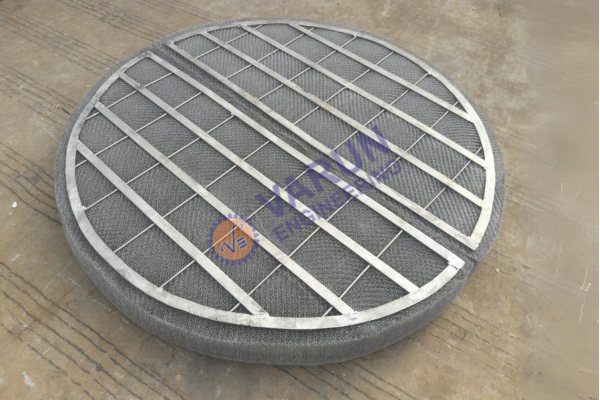

Have you ever wondered how industries maintain clean and efficient gas streams? The secret is a Demister Pad, a simple yet effective device that captures liquid droplets, allowing only clean gas to pass through.

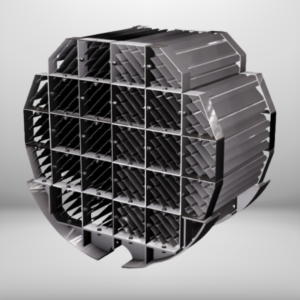

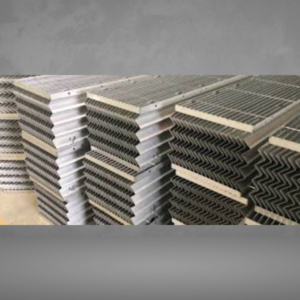

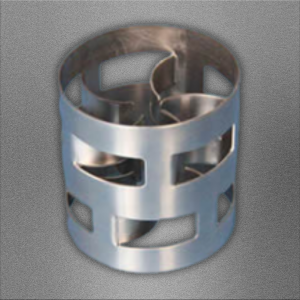

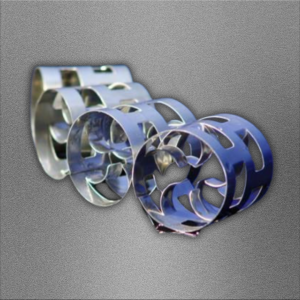

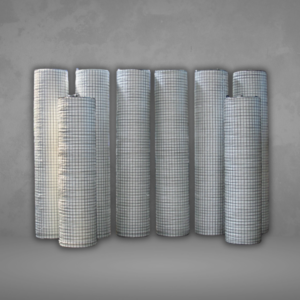

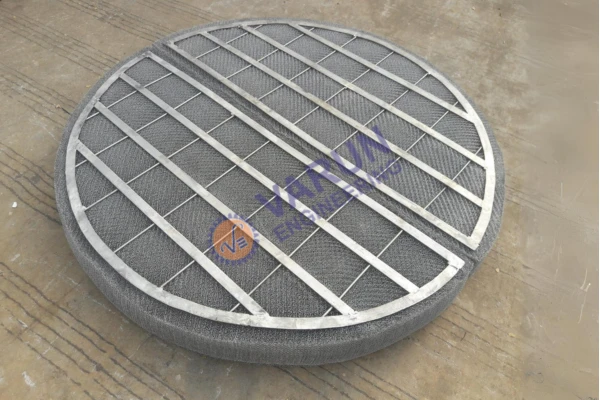

At Varun Engineering, we take pride in our high-quality Demister Pads, crafted from premium materials to withstand harsh conditions and deliver consistent results.

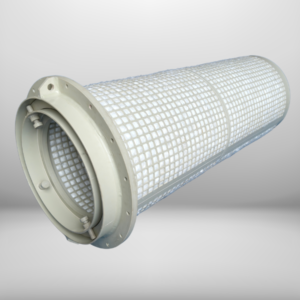

Designed to perfection for various industrial applications, our pads not only reduce pollution but also protect your equipment from damage, saving you time and money.

By preventing liquid carryover, they help you comply with environmental regulations and avoid costly fines. Easy to install and maintain, they are the hassle-free solution you’ve been looking for.

With years of expertise, we offer customized solutions tailored to your needs, ensuring durability and top-notch performance. Discover how Varun Engineering’s Demister Pads can enhance your operations and make a real difference in your industry.