Varun Engg. Candle filter Mist Eliminators are widely used in plants of:

Sulphuric Acid.

Phosphoric Acid.

Caustic Chlorine Units.

Hydrochloric Acid.

Fluorine Units.

Nitric Acid.

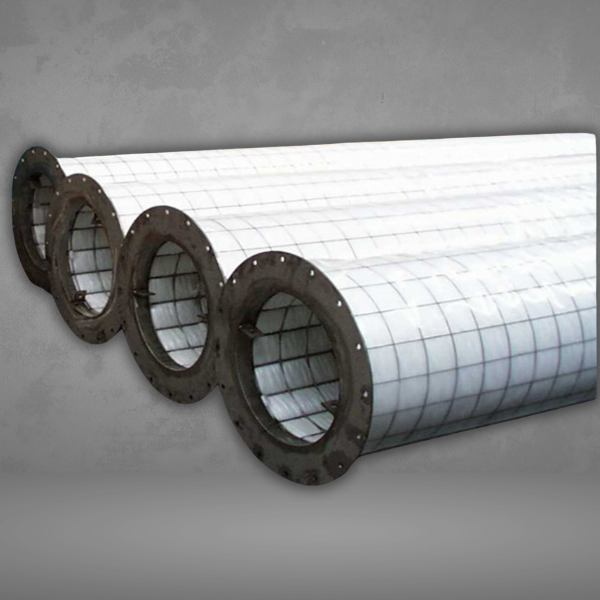

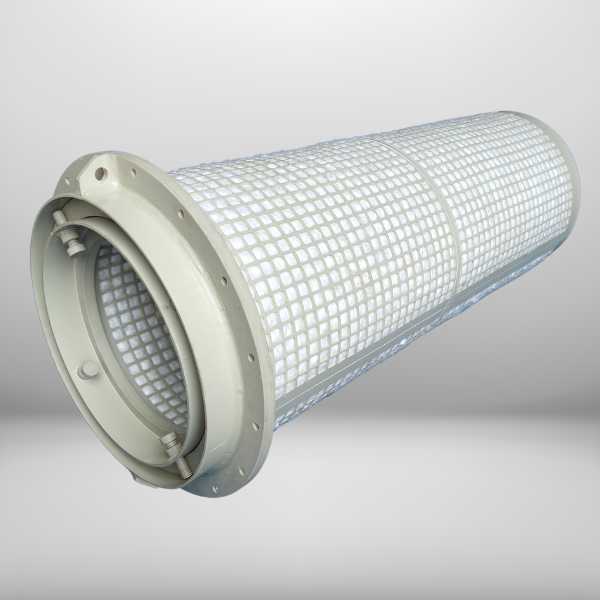

Manufactured throughout India with the correct and optimum materials of construction for the needs of duty and life, our specification is guaranteed. Glass fibre or polyester fibre filter elements, stainless steel, titanium, or resinated GRP cages are options to make certain that you get the best performance.

Where finer or submicron mist is a problem, the installation of a Candle Filter can remove 100% of mist >1 micron and 98% of mist <1 micron.

Our Candle Filters use a combination of impingement for removing particles >1-2 microns and diffusion for finer particles where Brownian motion becomes increasingly predominant.

WHAT IS A FIBRE BED MIST ELIMINATOR

A Candle Filter Mist Eliminator is a fibre bed into which Mist laden gases enter, and out of which emerges a clean gas stream and a separated liquid stream. Fibre packing in the bed is Engineered to provide High Separation Efficiencies.

As indicated, the bed consists of special fibres, which are densely packed between two screens. Mist-laden gases enter from the side of the bed and pass in a horizontal direction through the bed. Clean gases emerge from the bed and rise to exit from the mist eliminator. Separated liquids are directed downwards and towards the outer screen and ultimately drain down the outer edge of the bed.

Within a chemical process plant, it is necessary to remove acid mist and droplets from the gas stream which otherwise:-

Increase atmospheric emissions

We with our expertise can help you on this.

|

|

With our experience we can deliver customized solutions that can meet your requirements.

Most optimum product design for your new, existing or even aged plant.

Be it any situation we are well equipped for repair and replacements in any reasonable given time span.

Chlorine, Caustic and Hydrogen can be produced using electrolysis on common salts such as Sodium Chloride and Potassium Chloride. Electrolysis takes place and brine is extracted via Anode and Cathode cells on either side of the membrane.

Gas stream loaded with fine mist particles will enter the bed of densely packed fibers from one side, while from the other side clean gas will emerge. The liquid separated by either Brownian or Impaction methodology will drain off by gravity.

The liquid separated by either Brownian or Impaction methodology will drain off by gravity.