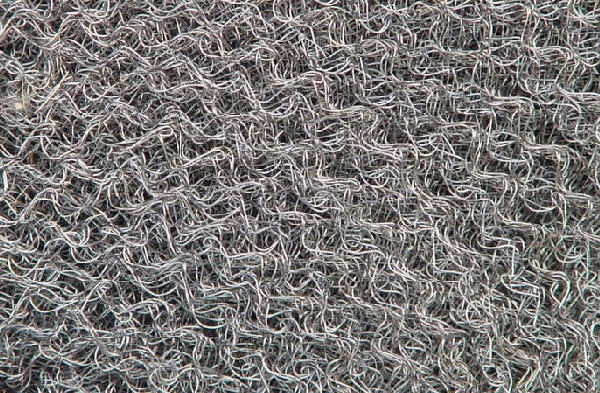

Compressed knitted Mesh is a special kind of material that is made by knitting metal.

In simple words, at home, generally metal scrubber can be seen for dish cleaning. And it is also like a sponge that can easily squeeze and get back to its natural shape.

Compressed knitted is just like it. It’s like both are working together. But it is made for big machines in factories, cars, planes, and even chemical plants.

Compressed knitted mesh is made with thin metal wires or plastic wires, just like knitting a sweater. But instead of wool or yarn, machines use strong wires such as stainless steel or copper.

After that, the flexible wire tube is pressed very hard in a machine called a die press. And this press squeezes the knitted wire and turns it into a solid, compact shape like a ring, disc, block, or cylinder.

In simple words, it starts like knitting a wire fabric, and then it gets pressed tightly. After pressing, it becomes stronger, softer and bouncier with lots of little gaps inside. And then this pathway helps the material to work like a sponge.

It looks like strong, soft and round metal. It feels solid metal, and it has many tiny twisted pathways that help to trap the mist, dust, and particles.

How Is Compressed Knitted Mesh Made?

- Knitting: It is a special machine that knits metal wires together. It is similar to how people knit socks or sweaters, but here the “thread” is metal wire.

- Making a Tube: The knitted mesh comes out like a long, stretchy tube — very flexible and soft.

- Cutting: This tube is cut into pieces depending on what size or type is needed.

- Compressing: Now the flexible piece is placed in a strong press. The press pushes it very hard, turning it into a solid and stable shape. This pressing step is what gives the material its final strength.

- Forming Special Shapes: Different industries need different shapes, so compressed knitted mesh can be made into: Rings, Discs, Cylinders, Blocks, and Pads.

Why Compressed Knitted Mesh Is So Strong?

This material is famous for being very tough, and here’s why:

- Materials: It is made from stainless steel, copper.

- Tiny Springs: in every knitted loop works like a mini spring. It also helps the material to bend without breaking.

- Handles Heat: It is made of metal and which does not melt or get damaged easily even at high temperatures.

- For a long time, it does not rust quickly and can survive in harsh factory conditions.

- It can absorb: It reduces shaking and noise inside machines, keeping them safe.

How Does Compressed Knitted Mesh Work?

- Compressed knitted mesh works like a smart metal sponge with many tiny pathways.

- These pathways help trap very small dust and dirt particles as air or liquid passes through.

- It can easily catch mist droplets and stop them from escaping into the environment.

- The mesh also helps separate gas and liquid in different industrial processes.

- Its strong metal loops absorb noise and vibration, keeping machines steady and quiet.

- Even when squeezed under pressure, the mesh springs back into shape.

- All this happens because of its twisted pathways and strong, flexible loops.

Where Is Compressed Knitted Mesh Used?

It has many uses:

- Filter: It is one of the most important uses in factories, engines, and chemical plants that use compressed knitted mesh to filter the gas, air, water, and oil. And especially in mist eliminators, it catches tiny droplets from the gas so that only clean gas passes through. It keeps the machine clean machine clean and reduces harmful chemicals.

- Absorbers: Cars, trains, and even aeroplanes use compressed knitted mesh to reduce vibration. They absorb movement and noise. It makes it safe, quiet, and smooth.

- Seals and Gaskets: In places with very hot temperatures, normal rubber or plastic seals cannot survive. So industries use compressed knitted mesh as high-temperature seals. It fits well, springs back, and does not melt, making it perfect for such jobs.

- Electronics: Electromagnetic Interference can disturb electronic devices. Compressed knitted mesh is used to block it. This is very useful in computers, communication equipment panels, and medical machines

- Chemical and Oil Industries: In big towers and columns inside chemical factories, compressed knitted mesh helps separate liquid and gas. It keeps the process clean and efficient.

Why Does Industrial Like to Use This Compressed Knitted Mesh?

- It is strong and it can be used for lasts long time.

- It works in high heat, and it can also be reused.

- It can be shaped easily.

- It can handle pressure and also handle high heat.

- It keeps machines safe, and it also improves performance.

Conclusion

Compressed knitted mesh may sound like a complicated engineering material, but at its core, it is simple and smart. Varun Engineering are here to give the best quality of compressed knitted mesh. That is not too strong and comes in good quality.

In Varun Engineering, you can also find pall rings, ceramic pall rings, and we also have lots of new products that make your work easy and safe.

Leave A Comment