Demister pads are crucial in various industries, tackling the task of separating liquid droplets from gas streams. This process delivers clean, dry gas ready for the next step. Often called mist eliminators or vapor pads, these devices shine in places like chemical plants, oil refineries, and pharmaceutical labs. This post dives into what demister pads are, how they function, their types, uses, benefits, and tips for picking the right one.

What Are Demister Pads?

Demister pads are clever tools designed to pluck tiny liquid droplets out of gas or vapor streams. These droplets, sometimes just a few microns in size, can wreak havoc if left behind, think corroded equipment or spoiled products. By capturing them, demister pads let the gas flow through spotlessly.

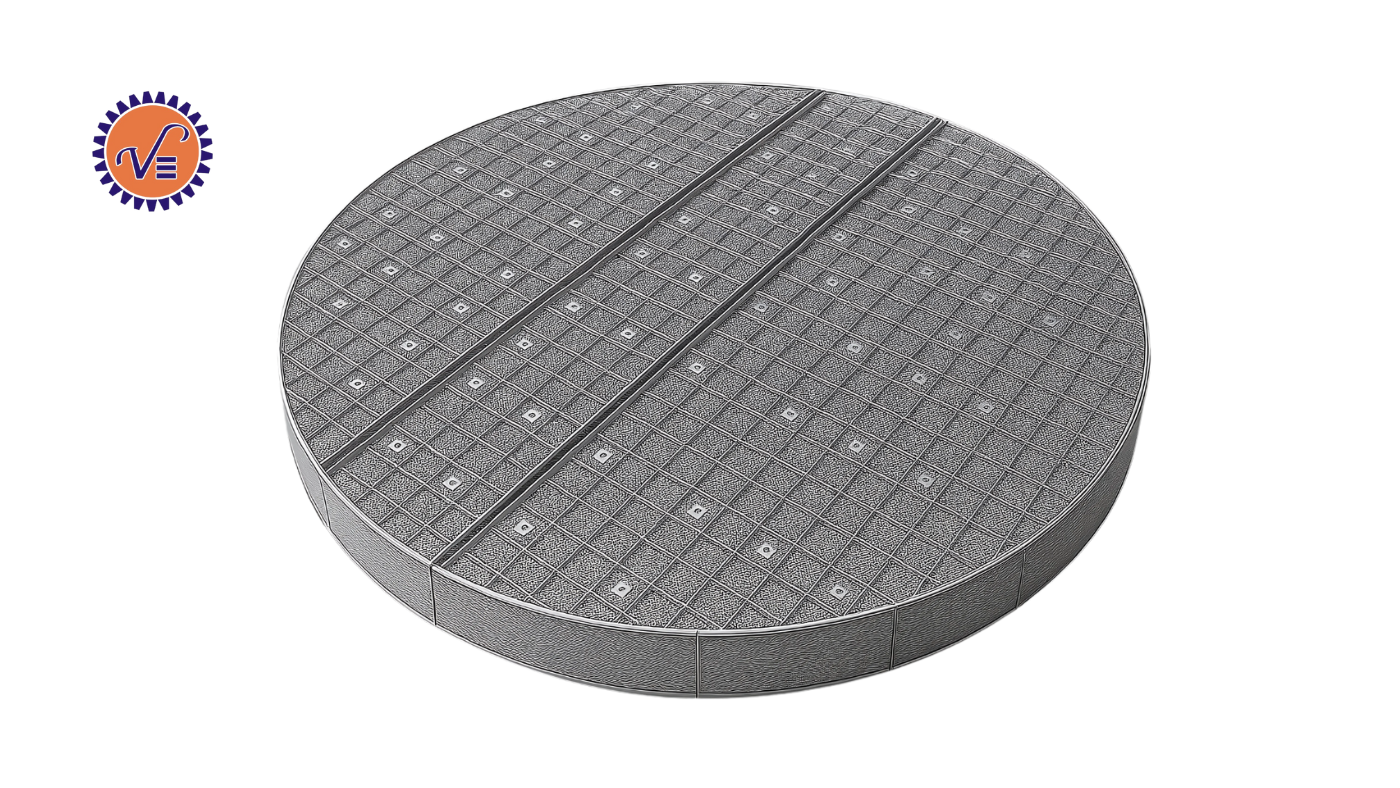

Usually crafted from knitted wire mesh or structured plates, these pads come in materials like stainless steel, plastic, or specialised alloys, depending on the job. They often sit at the top of gear like distillation columns or separators, ensuring only dry gas escapes. Their core mission? Boost gas stream quality, shield equipment, and keep operations humming along.

How Do Demister Pads Work?

Demister pads work in a simple yet effective way, relying on a process called coalescence, where tiny droplets team up to form bigger ones. Here’s the rundown:

- Gas Hits the Pad: A gas stream, loaded with liquid droplets, flows in.

- Droplets Collide: As the gas weaves through, droplets can’t dodge the wires or plates fast enough and smack into them.

- Merging Happens: Those droplets stick, joining forces with others to grow larger.

- Gravity Steps In: Big enough now, the drops slide down to the bottom for collection.

- Clean Gas Moves On: The gas, free of its liquid baggage, sails through.

Picture a coffee filter in action: it snags the grounds but lets the brew pass. Demister pads do the same, catching liquid while gas flows free. Success hinges on gas speed, droplet size, and pad design. Too fast, and some droplets sneak by; pads are built for specific rates to nail the job.

Types of Demister Pads

Demister pads come in two main flavours: mesh and vane, each with tricks up its sleeve.

Mesh Type Demister Pads

Mesh-type pads, woven from wire into a dense net, excel at grabbing droplets smaller than 10 microns. They’re perfect for jobs needing ultra-clean gas, like in pharmaceuticals or fine chemicals. Materials range from stainless steel for everyday use to polypropylene for corrosive spots. They shine in clean settings but can clog if dirt or sticky stuff builds up.

Vane Type Demister Pads

Vane-type pads feature parallel plates or zigzag vanes. Gas zips through, twisting and turning, while bigger droplets slam into the surfaces and get caught. These handle heavy liquid loads or grimy gases without clogging, making them stars in oil and gas setups, like scrubbing heavy oil mist. Often made of metal or plastic, stainless steel stands out for toughness.

Other Options

Variations abound within these types. Mesh pads tweak density for efficiency versus pressure drop. Some setups blend mesh and vane for extra punch in tough conditions. Specialized coalescer pads even team up to nab the tiniest droplets.

| Type | Best For | Droplet Size | Environment |

| Mesh Type | Tiny droplet cleanup | <10 microns | Clean or light fouling |

| Vane Type | Bigger droplets, heavy loads | >10 microns | Dirty or high liquid |

Where Demister Pads Shine

Demister pads pop up across industries, ensuring gas and liquid part ways cleanly. Here’s where they make a difference:

- Chemical Industry: In distillation columns, they stop liquid from sneaking into condensers. Scrubbers use them to zap acidic mists, safeguarding gear and emissions. Think sulfuric acid plants churning out fertilizers, demister pads keep things tidy.

- Petroleum Industry: Separators and scrubbers lean on them to strip oil or water from natural gas, keeping pipelines corrosion-free.

- Pharmaceuticals: They purify gases for pristine production, like in reactors crafting medicines.

- Power Generation: Steam turbines and boilers use them to dry steam, protecting blades and boosting efficiency.

- Environmental Protection: They scrub pollutants from exhaust or control moisture in wastewater systems.

- Food Industry: Evaporators rely on them to concentrate juices or dairy without losing quality.

From massive plants to niche labs, their versatility stands out.

Why Demister Pads Matter

Demister pads bring a slew of perks to the table:

- Top Efficiency: They nab up to 99% of droplets, keeping gas streams pristine.

- Low Pressure Drop: Gas flows easily, meaning systems run smoother and cheaper.

- Tough Against Corrosion: Stainless steel or alloys like Hastelloy laugh off harsh chemicals.

- Simple to Use: Installation’s a breeze, and cleaning or swapping them out takes little time.

- Tailored Fit: Shapes, sizes, and materials bend to fit any setup.

- Cost Savers: By blocking liquid carryover, they cut repair bills and boost product quality.

- Green Bonus: They trim emissions and recover chemicals, helping the planet and the bottom line.

These traits make them a go-to for gas-liquid separation.

Picking the Perfect Demister Pad

To choose wisely, weigh these factors:

- Droplet Size: Tiny ones under 10 microns? Mesh type wins. Bigger? Vane type does the trick.

- Liquid Load: High volume calls for vane pads; lighter loads suit mesh.

- Fouling Risk: Dirty gases favour vanes; cleaner ones work with mesh.

- Material Match: Stainless steel for most, plastics for corrosives, pick what fits the fluids.

- Conditions: High heat or flow? Special designs or alloys might be needed.

- Space: Custom pads can squeeze into tight spots.

Chatting with experts or manufacturers helps zero in on the best fit.

Wrapping Up

Demister pads keep industrial processes humming by stripping liquid from gas streams. They protect gear, lift product quality, and meet green standards. With stellar efficiency and flexibility, they’re everywhere, from chemical giants to power plants. At Varun Engineering, high-quality pads are tailored to unique needs, ensuring smooth, efficient operations. Reach out to see how these solutions can lift your business.