Mesh pack separators, often called demister pads or mist eliminators, are hardworking pieces of equipment found in industries like oil and gas, chemical processing, and wastewater treatment. These clever devices grab liquid droplets out of gas streams, making sure everything downstream stays safe and the output meets quality standards. But here’s the catch: without regular upkeep and a good scrub, they can’t keep doing their job well. This guide dives into why maintenance matters, walks through a hands-on cleaning process, shares practical tips, and troubleshoots everyday hiccups—all in plain, straightforward language. Whether you’re a pro or just getting started, these steps will help keep those separators humming along. And if top-notch equipment is on the radar, Varun Engineering has plenty of options worth checking out.

What Are Mesh Pack Separators?

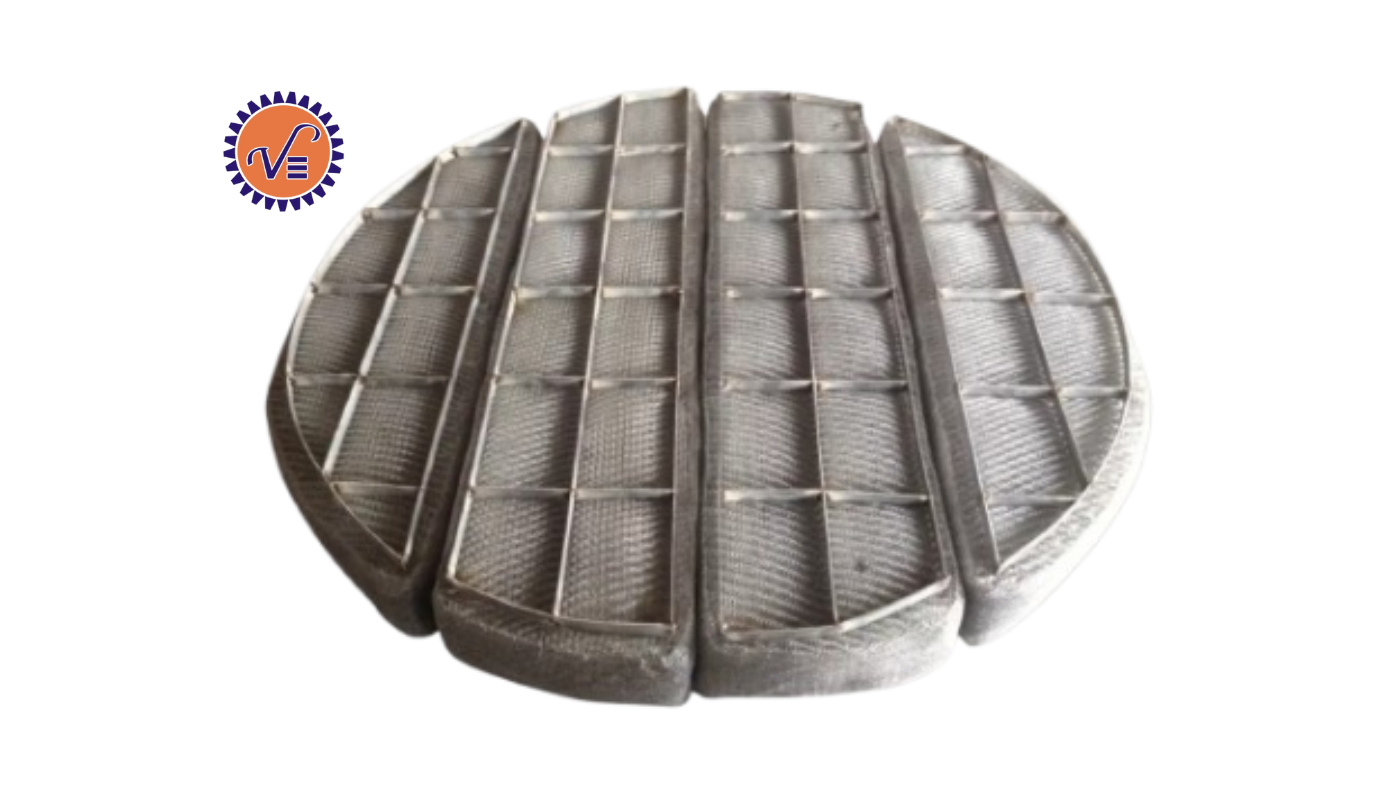

A mesh pack separator consists of stacked layers of woven or knitted wire mesh—made from stainless steel or polypropylene, depending on the application. As gas passes through, the mesh captures liquid droplets, causing them to coalesce and drain away. It’s a straightforward yet ingenious solution that delivers clean, dry gas ready for the next stage.

These separators pop up all over the place:

- Oil and gas: Stopping oil from sneaking into gas lines.

- Chemical plants: Keeping gases pure for reactions.

- Pharma: Ensuring clean processes.

- Power plants: Protecting turbines.

- Wastewater: Trapping unwanted liquids.

Everywhere they’re used, they’re quietly saving the day—assuming they’re kept in shape, of course.

Why Maintenance and Cleaning Are Essential

Think of maintenance as a lifeline for these separators. Here’s why it’s a big deal:

- No Clogs, No Drama: Dirt, oil, or gunk can pile up, choking the mesh and slowing everything down. That means more pressure, less flow, and a separator that’s barely pulling its weight.

- Top Performance: Clean mesh works like it should, catching every droplet it’s meant to.

- Longer Life: Regular care stops rust or wear from creeping in, saving replacement costs.

- Staying Legal: Rules in many industries demand clean outputs. A well-kept separator keeps fines at bay.

- Less Downtime: Catch problems early, and there’s no scrambling to fix a breakdown.

Skip this stuff, and trouble brews fast. Imagine liquid sneaking past a clogged separator into a compressor—yep, that’s a repair bill waiting to happen. Or worse, a spill that gets regulators knocking. It’s worth the effort to avoid those headaches.

Step-by-Step Guide to Cleaning Mesh Pack Separators

Cleaning these separators isn’t rocket science, but it takes care and a clear plan. Here’s how it’s done, step by step:

- Get Ready

- Stay Safe: Shut everything down and let the pressure out. Grab gloves, safety glasses, and maybe a coverall—better safe than sorry.

- Tool Up: Wrenches, screwdrivers, a cleaning solution that won’t harm the mesh, a soft brush, and a hose or spray bottle. Have them handy.

- Lock It Off: If the separator can be cut off from the system, do it. Keeps things clean and safe.

- Take It Apart

- Open Up: Pop off the access panels or hatches to get at the mesh packs.

- Pull the Mesh: Slide those mesh packs out gently. Jot down where they go—makes putting it back easier.

- Quick Peek: While it’s open, scan inside for any mess or wear worth noting.

- Clean the Mesh Packs

- Rinse First: A gentle spray of water knocks off loose junk. High pressure? Nope—that could wreck the mesh.

- Soak if Needed: Sticky stuff might call for a soak in a manufacturer-approved cleaner. Check the mesh type first.

- Brush Lightly: A soft brush works wonders on leftover grime. No need to scrub hard.

- Rinse Again: Wash off all the cleaner and bits with clean water.

- Dry It Out: Let it air dry or use a puff of compressed air. Wet mesh can rust or grow mold, so make sure it’s bone dry.

- Check for Trouble

- Spot Damage: Look close for rips or holes that could let stuff slip through.

- Rust Hunt: Metal mesh? Watch for corrosion, especially if harsh fluids are around.

- Shape Check: Make sure the mesh hasn’t bent out of whack during cleaning.

- Put It Back

- Reinstall: Slip the mesh packs back where they belong, lined up just right.

- Tighten Up: Secure clamps or bolts, but don’t overdo it—too tight can crush the mesh.

- Seal It: Close those panels and double-check the fit.

- Test Run

- Fire It Up: Start slow and listen for odd sounds or leaks.

- Pressure Check: Make sure the pressure drop looks normal.

- Sample It: Grab a quick test of the gas and liquid to confirm it’s working.

Maintenance Tips for Longevity

Want those separators to last? Here are some tricks to keep them going strong:

- Set a Routine: Depending on how hard the system runs, plan checks and cleanings—monthly for tough jobs, quarterly for lighter ones.

- Pick the Right Cleaner: Stainless steel can take a mild soap, but plastic mesh might need something gentler. Match the solution to the material.

- Store Smart: Spare mesh packs should sit in a dry, clean spot—no dust or dampness allowed.

- Train the Team: Everyone handling this should know the drill, from safety to steps.

- Keep Notes: Jot down when things get cleaned or fixed. It’s a goldmine for spotting patterns.

Here’s a handy schedule to tweak as needed:

| Task | Frequency | Notes |

| Visual inspection | Weekly | Look for signs of clogging or damage |

| Cleaning | Monthly | Use appropriate cleaning solution |

| Replace mesh packs | Annually | Or as needed based on inspection |

| Check seals and gaskets | Quarterly | Ensure no leaks |

| Lubricate moving parts | Semi-annually | If applicable |

Common Problems and How to Fix Them

Even with care, things can go sideways. Here’s what might come up and how to tackle it:

- Pressure Jumps Up

- Why: Mesh is clogged, drains are blocked, or something’s in the way.

- Fix: Clean the mesh, clear blockages, and check the system’s settings.

- Liquid Sneaks Through

- Why: Mesh is torn, put in wrong, or the flow’s too fast.

- Fix: Replace bad mesh, double-check setup, and tweak the flow.

- Rust Shows Up

- Why: Harsh fluids or wrong cleaners.

- Fix: Switch to tougher materials and use the right cleaning stuff.

- Rattles or Noise

- Why: Loose bits or a shaky frame.

- Fix: Tighten everything and check the structure.

Still confused? Call Varun Engineering, they might just have the answer.

The Environmental Impact of Proper Maintenance

Keeping these separators in shape isn’t just about the bottom line—it’s good for the planet too:

- Cleaner Air: No liquid carryover means fewer pollutants floating around.

- Less Waste: Good separation saves product and cuts trash.

- Rule-Friendly: Staying compliant keeps nature and neighbors happy.

Using green cleaners and tossing waste properly? That’s an extra win for sustainability.

Choosing the Right Mesh Pack Separator for Your Needs

Picking the perfect separator makes maintenance a breeze. Here’s what to think about:

- Material Match: It’s got to handle the process—titanium for nasty stuff, say.

- Mesh Tightness: Dense mesh grabs tiny droplets but might slow flow. Find the sweet spot.

- Size and Fit: Flow rate and space matter—get it right.

- Easy Access: Designs that open up quick save time.

Varun Engineering has a lineup that fits all kinds of jobs, so there’s likely one just right for the task.

Conclusion

Sticking to regular maintenance and cleaning keeps mesh pack separators doing their job—quietly keeping processes smooth and safe. These steps, tips, and fixes can stop trouble before it starts, stretch equipment life, and even help the environment a bit. It’s not the flashiest work, but it pays off big. And if new separators or advice are ever needed, Varun Engineering is ready to step up with solid gear and know-how.

Leave A Comment