First, let’s talk about boiler systems. They’re like the heart of many industries. Think power plants, factories, or even big heating systems. Boilers heat water until it turns into steam. That steam then does all sorts of jobs like powering machines or warming up buildings.

But here’s the catch: the steam needs to be good quality. By that, I mean it should be dry. Wet steam steam with water droplets in it can mess things up. How? Well, here are a few ways:

- Damage: Wet steam can hit parts like turbine blades and wear them out.

- Less Power: It doesn’t work as well for heating or moving things.

- Dirty Steam: In places like food factories, wet steam might carry dirt and ruin products.

So, we need a way to keep the steam dry. That’s where demister pads come in. They catch those pesky water droplets and let only clean steam move forward.

What Do Demister Pads Do in Boiler Systems?

Okay, let’s get into the main job of demister pads. In a boiler, there’s a part called the steam drum. It’s where the steam separates from the water. But sometimes, tiny water droplets tag along with the steam as it heads out.

That’s not good. So, we put a demister pad in the steam drum, usually near the top. The steam has to pass through it. When it does, the pad grabs those water droplets. The droplets stick together and get bigger. Then, they’re too heavy to float with the steam. They fall back down into the boiler. The steam keeps going nice and dry.

It’s a simple trick, but it works wonders. Without demister pads, wet steam could cause all sorts of headaches downstream.

How Do Demister Pads Work?

Now, how does a demister pad catch those tiny droplets? It’s pretty cool. Most demister pads are made of mesh. Think of it like a net with lots of small holes. The mesh can be metal like stainless steel or sometimes plastic.

When steam flows through this mesh, the water droplets bump into the strands. They stick there, like how raindrops cling to a window screen. As more droplets hit the mesh, they join up and make bigger drops. Eventually, those drops are heavy enough to drip back down.

It’s like nature in action. Ever notice how dew collects on the grass in the morning? The grass gives the water something to stick to. Demister pads do the same thing for steam. They provide water droplets a place to hang out so the steam can stay clean.

Why Are Demister Pads So Great?

Let’s talk about why demister pads are such a big deal. They bring a lot of good stuff to the table. Here’s a quick rundown:

1. They Save Your Equipment

Wet steam can be rough on machinery. In a power plant, for example, turbine blades don’t like getting hit by water droplets. It’s like sandpaper rubbing them down over time. Demister pads, stop that. They keep the steam dry, so your gear lasts longer.

2. They Boost Efficiency

Dry steam works better. It carries heat more effectively than wet steam. If you’re using steam to heat something, like in a factory, dry steam gets the job done faster. That means you use less steam and save energy. Who doesn’t love that?

3. They Keep Steam Clean

Some industries, like food or medicine, need super clean steam. Wet steam can carry dirt or germs. That’s a problem if you’re making food or drugs. Demister pads make sure the steam is pure by catching those droplets.

4. They Cut Maintenance Costs

When your equipment doesn’t get damaged by wet steam, you don’t have to fix it as often. Less repair time means less money spent. Plus, your boiler can keep running instead of sitting idle.

5. They Make Things Safer

Have you ever heard of Water Hammer? It’s when water in the steam pipes bangs around and causes damage. Wet steam can make that happen. Demister pads dry out the steam, so you’re less likely to deal with those nasty surprises.

Different Kinds of Demister Pads

Not all demister pads are the same. There are a few types out there. Each one has its strengths. Let’s check them out.

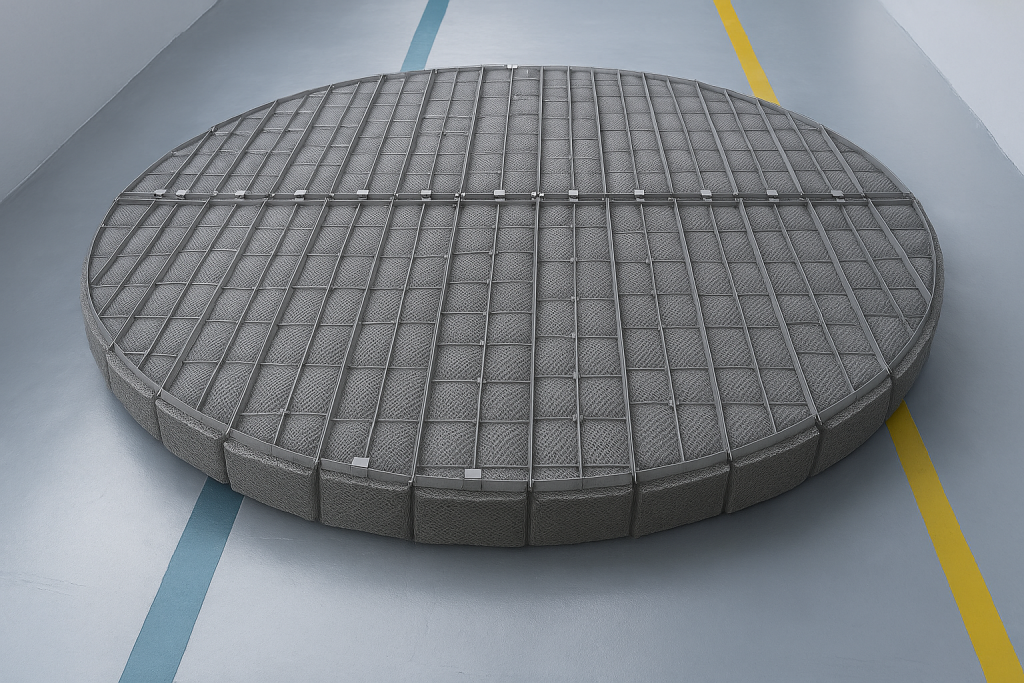

Wire Mesh Demister Pads

These are the most popular. They’re made of woven metal wires, usually stainless steel. Wire Mesh Demister Pads are especially effective at capturing fine mist and droplets in high-temperature environments. The mesh catches small droplets well. Plus, they’re tough. They can handle the heat and pressure inside a boiler. At Varun Engineering, this is our go-to type for most boiler systems.

Vane Type Demister Pads

These have flat plates or vanes instead of mesh. The steam zigzags through them. As it turns, the heavier water droplets crash into the plates and stick. Vane pads are great when there’s a lot of water to deal with or bigger droplets.

Fiber Bed Demisters

These use tiny fibers like glass or plastic to grab super-small droplets. They’re extra good at catching fine mist. But they can clog up faster, so they need more care. They’re perfect for special jobs, like in chemical plants.

We mostly stick with wire mesh at Varun Engineering. It’s reliable and works for most boilers. But if you need something different, we can make it happen.

How to Install and Take Care of Demister Pads

Putting a demister pad in your boiler isn’t too tricky. But you’ve got to do it right. Here’s what you need to know:

Where to Put It

The pad goes in the steam drum or at the boiler’s exit. It has to be where all the steam flows through. That way, it catches everything before the steam heads out.

Getting the Size Right

Size matters here. Too small, and it might slow down the steam too much. It’s too big, and it won’t grab all the droplets. We at Varun Engineering can figure out the perfect size for your setup.

Holding It in Place

You don’t want the pad flying around inside the boiler. It needs a frame or grid to keep it steady. That keeps it working like it should.

Keeping It Clean

Over time, demister pads can get dirty. Stuff like scale or rust builds up. That makes them less effective. So, you need to check them now and then. If they’re clogged, give them a rinse. For our stainless steel pads, a blast of water usually does the trick. If they’re too worn out, swap them for a new one.

With a bit of care, these pads can last years. We’ll give you all the tips you need when you get one from us.

Varun Engineering’s Demister Pads

Here at Varun Engineering, we’re proud of our demister pads. We’ve been making them for a while, and we know what works. Our pads are built from top-notch stainless steel. That means they can take the heat and last a long time.

We’ve got standard sizes that fit most boilers. But every system is different. If you need something custom, we’ve got you covered. Our team can design a pad just for your setup.

We don’t just sell pads we help you out. Need advice on picking the right one? We’re here. Questions about installing it? We’ve got answers. Our goal is to keep your boiler running like a champ.

Plus, our pads save you money in the long run. They cut down on repairs and keep your system efficient. It’s a win-win.

Conclusion

So, there you have it. Demister pads are a game-changer for boiler systems. They keep your equipment safe, make things more efficient, and clean up your steam. They save you money and headaches, too.

At Varun Engineering, we’re all about making the best demister pads out there. We want your boiler to run its best. If you’re thinking about adding a demister pad or wish to chat about it reach out.

Read More: https://medium.com/@varunenggs