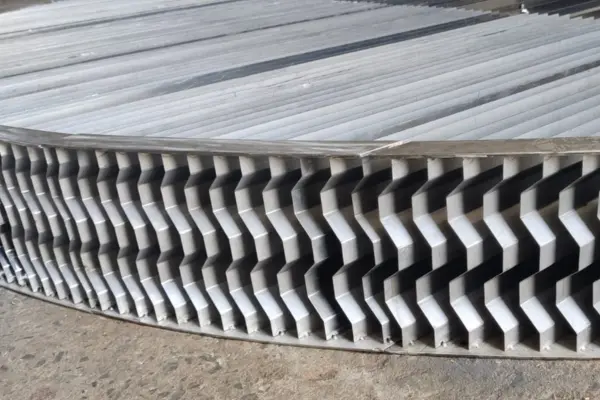

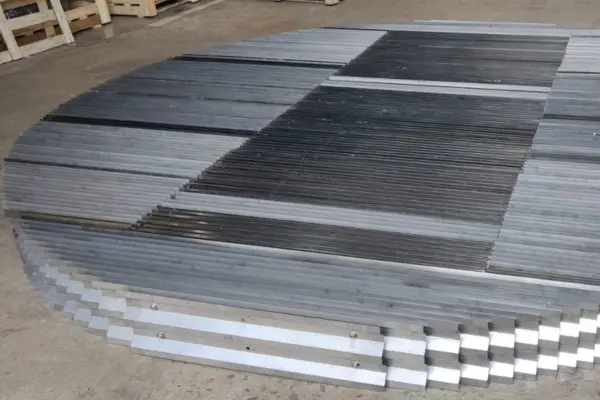

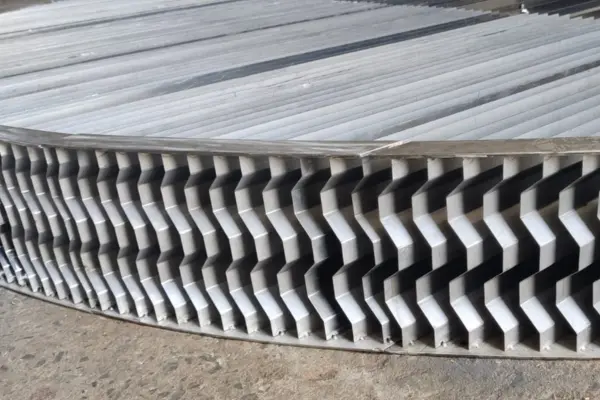

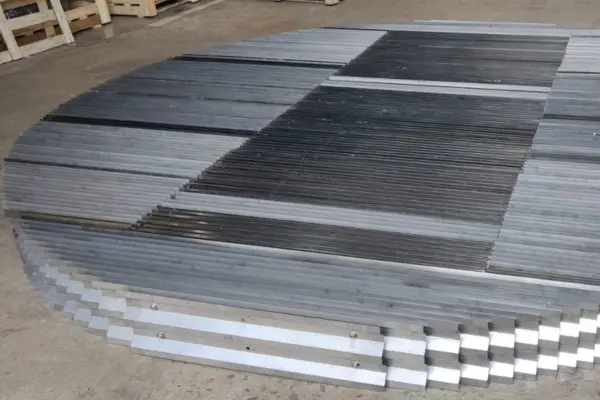

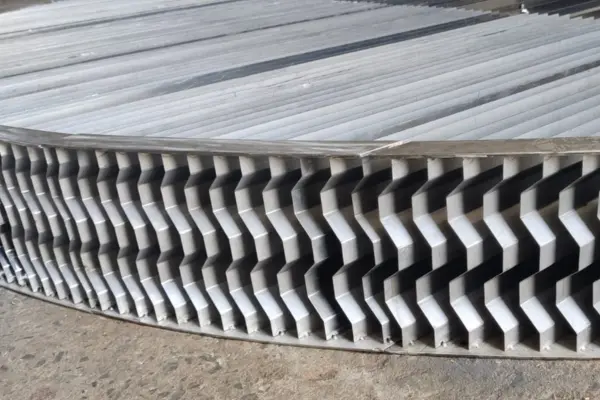

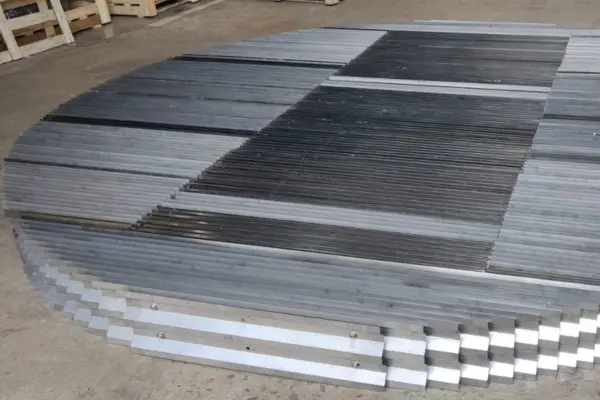

A vane pack chevron is a specialized type of mist eliminator used in industrial processes to efficiently remove liquid droplets from gas streams. It consists of multiple layers of vanes arranged in a chevron pattern, designed to maximize surface area contact with the gas stream and enhance droplet capture efficiency.

When gas carrying liquid droplets passes through the vane pack chevron, the vanes create a tortuous path that forces the droplets to collide and coalesce. As droplets grow in size, they adhere to the surfaces of the vanes and eventually drain away as collected liquid. The cleaned gas exits the mist eliminator, ensuring a purified gas stream free from moisture.

Vane pack chevrons are indispensable in industries such as petrochemicals, refineries, chemical processing, and natural gas processing plants. They are used in applications where high liquid loads and stringent purity requirements necessitate efficient mist elimination.

A vane separator is a type of mist eliminator designed to separate liquid droplets from gas streams by using a series of angled vanes. These vanes create a barrier that intercepts and collects liquid droplets entrained in the gas flow, ensuring that the gas leaving the system is free from moisture.

As the gas stream passes through the vane separator, the velocity of the gas causes liquid droplets to impinge on the vanes. The vanes are strategically placed to maximize droplet capture efficiency while allowing the gas to continue its flow path. Captured liquid droplets coalesce and drain away from the vanes, preventing them from entering downstream equipment.

Vane separators are widely used in industries such as pharmaceuticals, food processing, power generation, and wastewater treatment. They are essential in processes where maintaining gas purity and preventing equipment corrosion are critical.

A chevron mist eliminator is a type of mist eliminator characterized by its chevron-shaped vanes or baffles. These vanes are designed to disrupt the flow of gas and force liquid droplets to collide and coalesce, thereby separating them from the gas stream effectively.

Gas laden with liquid droplets enters the chevron mist eliminator, where the chevron vanes create a turbulent flow pattern. This turbulence causes the droplets to impact on the vanes and merge with other droplets, growing in size until they are too heavy to remain in the gas flow. The captured liquid then drains away from the eliminator, leaving a clean gas stream.

Chevron mist eliminators find applications in gas processing plants, chemical refineries, oil refineries, and air pollution control systems. They are essential in processes where maintaining environmental standards and operational efficiency is crucial.

By integrating vane pack chevrons, vane separators, and chevron mist eliminators into its processes, Varun Engineering ensures optimal performance and reliability in separating liquid droplets from gas streams, enhancing operational efficiency and equipment longevity.