Droplet separators, often called demisters or mist eliminators, serve an essential function in numerous industrial settings. These components extract liquid droplets from gas flows, resulting in purer emissions, safeguarded machinery, and enhanced operational effectiveness. Selecting a suitable droplet separator for a particular use presents difficulties due to the diverse options and elements involved. This article offers a straightforward guide to assist in identifying the optimal droplet separator for various industrial demands.

Understanding Droplet Separators

Droplet separators function through the inertia principle, dividing the process into primary and secondary phases. During primary separation, gas-containing droplets passes through curved vanes, where inertia forces droplets to stray from the gas path and hit the vanes, creating a liquid layer. Efficiency gets measured via the fractional separation degree, with bigger limit droplets removed here. Secondary separation clears the liquid layer from the gas using designed chambers or grooves, keeping pressure loss low. Designs change according to gas flow direction vertical or horizontal and specific needs.

These separators find use in sectors such as chemicals, petroleum, energy production, and water purification. The primary aim involves stopping liquid transfer, which might harm later equipment, lower process output, or create ecological problems.

Various droplet separator kinds exist, like vane-type, mesh demisters, coalescers, and candle filters. Each possesses distinct characteristics fitting certain uses. Grasping the demands of the operation marks the initial move in a wise selection.

Key Factors to Consider

Picking the appropriate droplet separator requires assessing multiple elements. The following represent the crucial points:

1. Process Conditions

System operating states heavily impact droplet separator selection. Vital aspects encompass:

- Gas Flow Rate: Elevated rates demand separators capable of managing big amounts without blocking or high pressure reduction.

- Temperature: Certain separators excel in extreme heat or cold. Materials and builds must endure the working heat.

- Pressure: High-pressure setups need strong separators to prevent bending or breakdown.

- Liquid Load: Liquid quantity in the gas affects separator output. Heavy loads might need custom builds.

For instance, a facility handling hot, corrosive gases requires a separator from tough, anti-corrosion substances.

2. Droplet Size

Liquid droplet dimensions in the gas stream play a key role. Tiny droplets under 10 microns prove tougher to catch and could need efficient separators such as fine mesh or candle filters. Bigger droplets over 20 microns often get managed by basic vane or cyclone types. Knowing droplet size spread aids in limiting choices.

Droplet size directly influences separator pick. Profiles suit droplets above 15 microns in high gas flow to cut pressure drop. Demisters handle over 5 microns with layered knit mesh. Coalescers target 2-5 microns using composite fabric. Candle filters work for under 2 microns with fiber bundles.

3. Material Compatibility

Separator materials must match the gas and liquid present. Usual options include:

- Stainless Steel: Fits harsh settings like chemical facilities.

- Plastic (e.g., PP or PVDF): Good for mild heat, non-harsh uses.

- Special Alloys: For severe states, like intense heat or strong corrosion.

Wrong material picks can cause rust, shorter life, or pollution. Always verify gas and liquid traits for fit.

4. Efficiency Requirements

Efficiency shows droplet removal success from gas. Some uses, like drug making, need almost total removal for tight rules. Others, like air systems, allow less. Mesh demisters give high output for small droplets, vane types suit bigger ones with less pressure fall.

5. Pressure Drop

Pressure drop means gas pressure cut through the separator. Big drops can lower system output and raise power costs. Vane separators usually show lower drops than mesh, fitting where pressure upkeep matters. Check allowed drop before pick.

6. Maintenance and Cleaning

Certain separators need routine cleaning to stop blocking or dirt buildup. Mesh types might gather solids, cutting output. Vane kinds often clean easier. Think about cleaning plan and access to cut stops and expenses.

7. Space and Installation Constraints

System space can restrict separator size and kind. Small builds like cyclones fit tight spots. Bigger setups hold mesh or vane. Also, consider horizontal or vertical setup, as it impacts build and output.

8. Cost Considerations

Funds always factor in. High-output separators might give better results but cost more. Weigh start price against long gains like less upkeep, lower power, and better reliability. A proper pick from a reliable source like Varun Engineering provides good worth over time.

Types of Droplet Separators

Knowing different droplet separator kinds helps in right pick. Common ones follow:

Mesh Pad Demisters

Mesh demisters use woven or knit mesh to catch droplets. They excel for tiny droplets and see wide use in chemical and oil sectors. Yet, they might block with high solids or thick liquids.

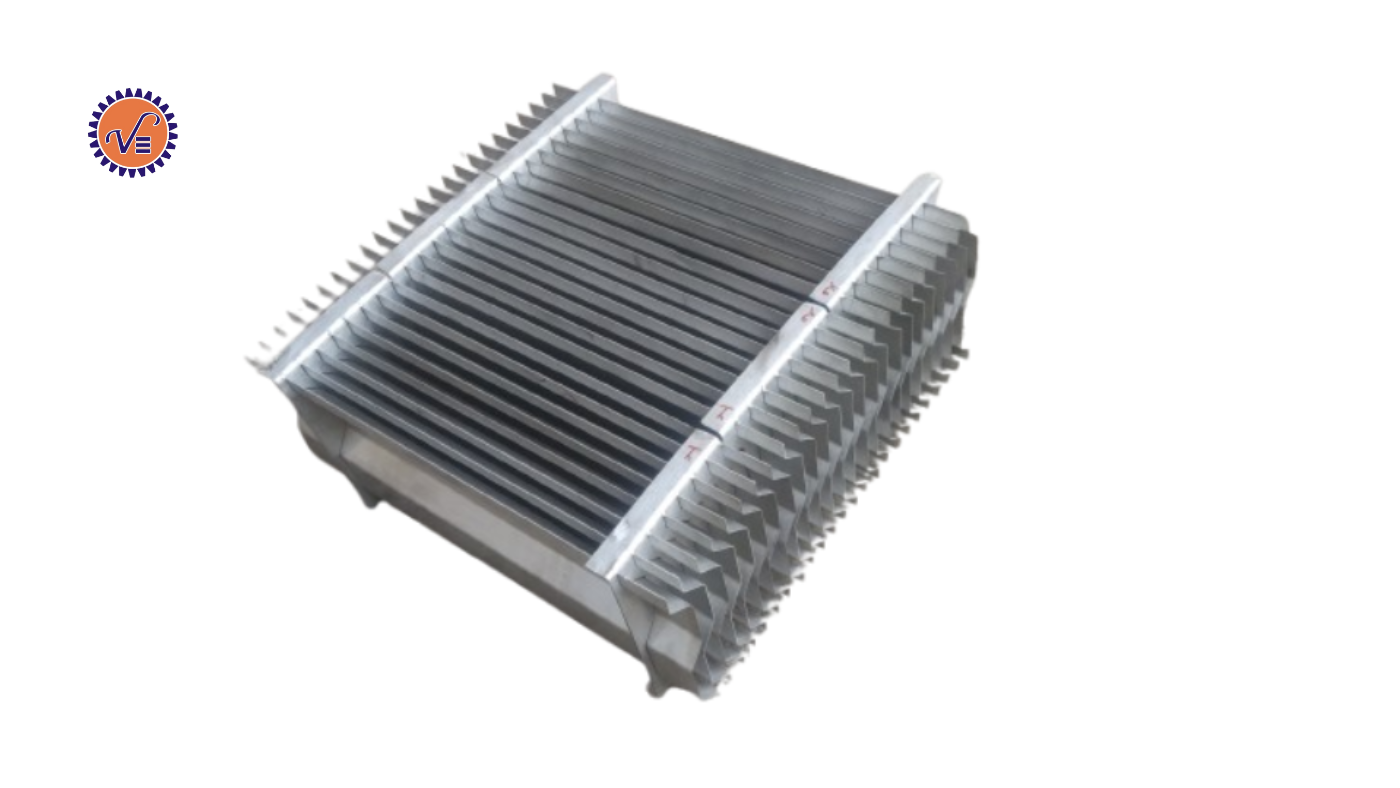

Vane-Type Separators

Vane separators employ plates or vanes to shift gas flow, making droplets hit and split. They fit high gas rates and bigger droplets. Durable and simple to maintain, they suit oil and gas.

Cyclone Separators

Cyclone types use spin force to remove droplets. Compact and good for heavy liquid loads, but might miss very small droplets. Often used in water treatment or power.

Other Types

Coalescers handle mid-size droplets with special fabric. Candle filters target tiniest with fibers.

Sizing Droplet Separators

Sizing uses methods like droplet settling theory or Souders-Brown. Souders-Brown finds max gas speed to avoid liquid drag with formula involving density and sizing factor. Factor depends on pressure, fluids, shape, inlet, and mist type like mesh or vane.

For vertical, full cross-area for gas; horizontal, adjust for liquid level. Use tables for factors, trial for horizontal length-diameter ratio 3-6.

Steps to Choose the Right Droplet Separator

These steps guide to best pick:

- Define the Application: Note industry, process, specifics like gas rate, droplet size, heat.

- Evaluate System Conditions: Collect data on heat, pressure, liquid load, chemical traits.

- Determine Efficiency Needs: Set droplet removal importance.

- Consider Maintenance and Space: Check space, setup direction, upkeep ease.

- Compare Separator Types: Align needs with mesh, vane, cyclone strengths.

- Check Material Compatibility: Confirm material fits gas, liquid.

- Consult Experts: Team with makers like Varun Engineering for custom, support.

- Balance Cost and Performance: Pick meeting output in budget.

Common Applications of Droplet Separators

Separators apply in many fields. Examples:

- Chemical Processing: Clear harsh droplets to guard gear.

- Oil and Gas: Split oil/water from gas in plants.

- Power Generation: Stop water in steam units.

- Wastewater Treatment: Catch droplets in scrubbers for less emissions.

- Pharmaceuticals: Keep gas clean for delicate makes.

- Shipbuilding: Scrubbers for exhaust, air intake protection.

- Food Industry: Evaporation in juice, sugar; distillation.

- Metallurgy: Gas clean in scrubbers, emission cut.

Each field has unique demands, so grasp specifics for success.

Tips for Optimal Performance

For top separator work:

- Regular Inspections: Look for dirt, rust, harm to keep output.

- Proper Installation: Follow maker rules for right place, fit.

- Monitor System Changes: Adjust if flow or load shifts.

- Work with Trusted Suppliers: Join experienced makers for quality, aid.

- Use CFD Analysis: For complex, simulate to optimize.

- Consider Cleaning Systems: For dust loads, add for ongoing run.

Conclusion

Selecting the proper droplet separator demands thorough review of process states, droplet size, material fit, efficiency, upkeep. By grasping the use and checking options, the ideal separator ensures steady work and lasting worth. Reliable makers like Varun Engineering supply varied separators for diverse needs. Spend time to evaluate system, seek advice, invest in efficient, durable solution.