Ever wonder how factories keep their air clean and protect their equipment from tiny liquid droplets floating around? That is where mist eliminators come in to rescue. These clever devices, built by companies such as Varun Engineering, take care of the mist problem in industrial processes. This blog elaborates on what mist eliminators are, how they eliminate mist, and why their application is important in chemical plants, oil refineries, and power stations. In simple, colloquial terms, this guide stays simple and real like a chit-chat over coffee.

Understanding Mist Eliminators

A mist eliminator is a device that will weed out those tiniest of liquid droplets essentially called mist from gas streams. Now imagine a factory where, from boling or spraying to various chemical reactions, fine droplets get created maybe with air or gas. If those droplets escape out, they contaminate the machines, pollute the ambient, or spoil products. The mist eliminators work something like a strainer to catch the liquid with the clean gas passing through.

Varun Engineering manufactures such devices for practically all industries—chemical plants, oil and gas facilities, power plants, even food factories. They are built to ensure the smooth running of operations, safeguard equipment, and comply with environmental laws.

Why Mist Eliminators Matter

Mist forms in industrial processes for a few reasons:

- Cooling Down: Hot gas cools, and vapor turns into tiny droplets, like morning fog.

- Mechanical Processes: Spraying liquids, mixing, or boiling can break liquids into droplets that get carried by gas.

- Chemical Reactions: Some reactions release liquids that form mist in the gas.

If this mist isn’t dealt with, it causes trouble:

- Damaged Equipment: Droplets can rust pipes, wear out turbines, or clog systems, leading to expensive fixes.

- Pollution: Mist carrying chemicals can escape into the air, breaking environmental laws.

- Product Problems: In places like drug or food factories, mist can contaminate batches, wasting time and money.

- Safety Hazards: Toxic or flammable mist can put workers or nearby areas at risk.

Mist eliminators stop these issues by grabbing droplets before they cause harm. Varun Engineering builds solutions tailored to each industry’s needs, keeping things running smoothly.

How Mist Eliminators Do Their Job

Mist eliminators work by separating liquid droplets from gas in a straightforward way. Here’s how it happens:

- Gas Flows In: Gas mixed with tiny droplets enters the mist eliminator, usually inside a vessel, tower, or pipe.

- Droplets Hit a Barrier: The eliminator has a surface—think mesh, plates, or fibers—that makes the gas twist and turn. Droplets, being heavier, can’t keep up and smack into the surface.

- Droplets Combine: Once stuck to the surface, droplets merge into bigger drops, a process called coalescence. Bigger drops are easier to separate.

- Liquid Drains Off: The heavier drops slide down due to gravity and collect in a container or flow back into the process.

- Clean Gas Moves On: The gas, now free of most droplets, continues through the system or gets released safely.

Varun Engineering designs these devices to catch as many droplets as possible without slowing down the gas flow too much, saving energy and keeping things efficient.

Different Kinds of Mist Eliminators

Not all mist eliminators are the same. Varun Engineering offers several types, each suited to specific jobs. Here’s a rundown of the main ones:

1. Wire Mesh Mist Eliminators

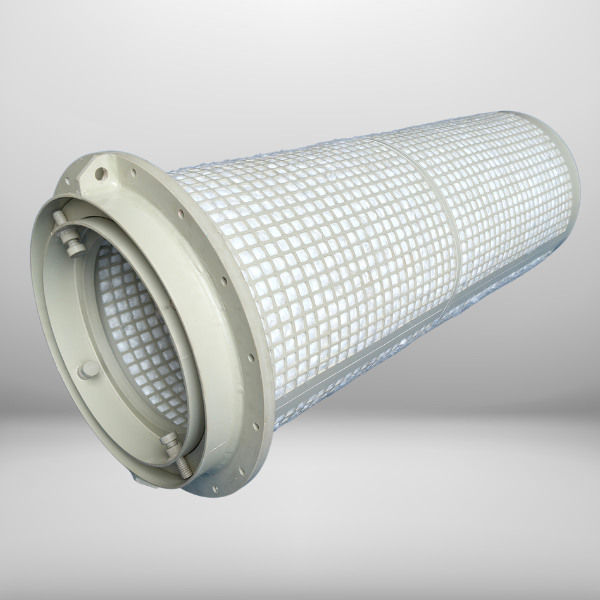

These are the most common type, made of knitted or woven metal wires, like stainless steel, forming a thick pad. Gas passes through, but droplets get caught.

- How They Work: The mesh acts like a net, snagging droplets as they try to follow the gas. The droplets stick, combine, and drip down.

- Benefits: They catch up to 99% of droplets as small as 2 microns, cost less, and are easy to set up.

- Uses: Found in chemical plants, oil refineries, and gas scrubbers.

- Example: In a fertilizer plant, wire mesh eliminators grab acid mist to protect pipes from rusting.

2. Vane-Type Mist Eliminators

Mist Eliminator Vane Pack systems use angled plates or blades to redirect gas flow. Droplets crash into the blades and get separated, ensuring efficient removal of liquid particles from the gas stream.

- How They Work: Gas weaves through the vanes, and droplets, too heavy to turn, hit the plates and slide down.

- Benefits: Great for fast-moving gas or when solids are mixed in. They don’t clog easily and keep gas flowing smoothly.

- Uses: Common in cooling towers and power plant exhaust systems.

- Example: In a coal power plant, vane eliminators remove water droplets from scrubber exhaust to protect turbines.

3. Fiber Bed Mist Eliminators

These use fine fibers, like glass or plastic, packed between screens. They’re built for tiny droplets.

- How They Work: Gas flows through the fibers, where droplets collect and form liquid films that drain away.

- Benefits: Perfect for droplets smaller than 1 micron, offering top-notch efficiency.

- Uses: Used in chemical plants and air pollution control.

- Example: In a drug factory, fiber bed eliminators keep air clean for sterile production.

4. Cyclone Mist Eliminators

Cyclone eliminators spin gas in a cylindrical chamber, using centrifugal force to fling droplets to the walls.

- How They Work: The spinning motion pushes droplets outward, where they hit the walls and drain.

- Benefits: Handle larger droplets and heavy liquid loads well.

- Uses: Found in oil and gas separators and wastewater systems.

- Example: In an oil refinery, cyclone eliminators pull oil mist from gas streams for cleaner output.

Varun Engineering picks the right type based on the job, ensuring the best results for each client.

How Droplets Get Caught

Mist eliminators rely on three key ways to trap droplets:

- Inertial Impaction: Bigger droplets (20-30 microns) move straight and crash into the eliminator’s surface because they can’t follow the gas’s curves.

- Direct Interception: Medium droplets (1-3 microns) stick to surfaces as they brush past, even if they follow the gas.

- Brownian Diffusion: Tiny droplets (under 1 micron) wiggle randomly due to gas molecule collisions, making them more likely to hit the eliminator.

These methods team up to remove 97-99% of droplets, depending on the eliminator’s setup.

Where Mist Eliminators Shine

Mist eliminators are used in all sorts of industries to tackle specific problems. Varun Engineering builds devices to match each sector’s needs. Here’s a look at where they’re used:

1. Chemical Plants

Chemical processes often create corrosive mists, like sulfuric or hydrochloric acid mist. These can eat away at equipment or pollute the air. Mist eliminators catch these droplets to keep things safe.

- Example: In a fertilizer plant, wire mesh eliminators stop acid mist, protecting pipes and meeting emission rules.

- Varun Engineering’s Role: Custom mesh pads handle tough chemicals and high heat.

2. Oil and Gas

Refineries and gas plants deal with oil mist, water droplets, and hydrocarbon aerosols. Mist eliminators keep these from damaging equipment or lowering product quality.

- Example: In a gas separator, a cyclone eliminator removes oil mist, ensuring purer gas.

- Varun Engineering’s Role: Vane and cyclone designs work in high-pressure systems and resist sticky hydrocarbons.

3. Power Plants

Power plants, especially those with flue gas desulfurization (FGD), use mist eliminators to clean exhaust gases of water and acid droplets, protecting turbines and cutting emissions.

- Example: In a coal plant, vane eliminators clear water droplets from scrubber exhaust, saving turbine blades.

- Varun Engineering’s Role: Durable vanes handle high gas flows with little upkeep.

4. Wastewater Treatment

Single-effect wastewater evaporators produce vapor with droplets. Mist eliminators ensure clean vapor for condensing or release.

- Example: In an evaporator, a wire mesh eliminator captures droplets for high-quality distilled water.

- Varun Engineering’s Role: Custom designs handle corrosive wastewater and solids.

5. Food and Drug Industries

These sectors need clean, sterile air. Mist eliminators remove moisture or chemical droplets to avoid contamination.

- Example: In a drug plant, fiber bed eliminators keep air sterile for production.

- Varun Engineering’s Role: High-efficiency fiber beds meet strict hygiene standards.

6. Cooling Towers

Cooling towers release water droplets that can carry contaminants. Mist eliminators cut water loss and protect the environment.

- Example: Louver-type eliminators in cooling towers trap droplets, saving water.

- Varun Engineering’s Role: Lightweight, corrosion-resistant vanes are easy to install.

Why Use Mist Eliminators?

Mist eliminators bring a lot to the table:

- Equipment Protection: They stop corrosive droplets, making pipes and turbines last longer.

- Cleaner Air: Capturing pollutants helps meet environmental rules.

- Better Products: Clean gas streams prevent contamination in sensitive industries.

- Lower Costs: Less damage and clogging mean fewer repairs and less downtime.

- Safer Workplaces: Removing toxic or flammable mist reduces risks.

- Resource Savings: Captured liquids can often be reused, cutting waste.

Varun Engineering’s designs maximize these benefits, offering solutions that fit each industry.

Choosing the Right Mist Eliminator

Picking the best mist eliminator depends on a few things. Varun Engineering works with clients to get it right. Key factors include:

- Gas Flow: Fast-moving gas needs vane eliminators; slower flows work with mesh pads.

- Droplet Size: Fiber beds catch tiny droplets, while vanes handle bigger ones.

- Liquid Load: High liquid amounts need good drainage, like cyclone designs.

- Conditions: Temperature, pressure, and chemical harshness guide material choices (e.g., stainless steel or plastic).

- Upkeep: Mesh pads are easy to clean; vanes resist clogging.

Varun Engineering analyzes these to deliver the best fit.

Keeping Mist Eliminators in Top Shape

Regular care keeps mist eliminators working well. Here’s how:

- Cleaning: Rinse mesh pads with water to clear buildup. Dry them to avoid rust.

- Checks: Look for clogs, corrosion, or damage, especially in tough conditions.

- Replacement: Mesh pads may need swapping every few years.

- Monitoring: Watch pressure drop to catch blockages early.

Varun Engineering offers tips and support for long-lasting performance.

Varun Engineering’s Edge

Varun Engineering stands out for good reasons:

- Custom Solutions: Each eliminator is built for the client’s specific needs.

- Tough Materials: Options include stainless steel, polypropylene, and corrosion-resistant alloys.

- Expert Help: From design to setup, the team ensures everything works perfectly.

- Versatile Uses: Solutions fit industries from oil to pharmaceuticals.

- Eco-Friendly Focus: Designs save energy and meet environmental standards.

Clients rely on Varun Engineering for dependable, cost-effective mist eliminators.

Challenges and Fixes

Mist eliminators face some hurdles, but there are solutions:

- Re-entrainment: High gas speeds can pull droplets back into the flow. Fix: Design with proper speed limits using the Souders-Brown equation.

- Clogging: Solids can block mesh pads. Fix: Use vanes or clean regularly.

- Corrosion: Harsh chemicals can damage materials. Fix: Choose tough materials like PTFE or stainless steel.

- Pressure Drop: Bad designs slow gas flow. Fix: Optimize for low pressure drop, as Varun Engineering does.

These fixes ensure reliable performance in tough settings.

What’s Next for Mist Eliminators?

As industries push for cleaner, more efficient operations, mist eliminators will evolve:

- New Materials: Stronger alloys and plastics will handle harsher conditions.

- Smart Tech: Sensors could monitor performance and flag maintenance needs.

- Energy Savings: Designs will focus on less resistance to gas flow.

- Sustainability: More systems will reuse captured liquids, cutting waste.

Varun Engineering is already working on these advancements.

Why Go with Varun Engineering?

Varun Engineering brings years of know-how to the table. Their mist eliminators are:

- Made to Fit: Designed for each client’s unique process.

- Built to Last: Use tough materials for harsh conditions.

- Budget-Friendly: Low upkeep and long life save money.

- Backed by Experts: A team helps with design, setup, and care.

From chemical plants to power stations, Varun Engineering delivers results.

Wrapping Up

The mist eliminators could definitely be classified as unsung heroes of the industry, with their role in protecting equipment from corrosion, maintaining clean air, and ensuring product purity by arresting fine-size liquid droplets in gaseous streams. Wire mesh mist eliminators, vane mist eliminators, fiber bed mist eliminators, and cyclones find their place in chemical plants, refineries, and power stations alike. Custom engineered solutions make Varun Engineering the premier option for mist-related problems.

Knowing how mist eliminators function and their perks allows industries to make wise decisions concerning economy, safety, and environment. Higgins Engineering is the name to stand for when looking to buy a mist eliminator that fits the bill.