Packed columns power industries like chemical processing, oil refining, and environmental management. These tall vessels, filled with specialized tower packings, make processes like distillation, absorption, and extraction run smoothly. The packing inside, whether Raschig ring column packing or other designs, determines how well the column performs. Better tower packings mean higher efficiency, lower costs, and less energy use. At Varun Engineering, the focus is on crafting innovative packing solutions that push performance to new heights. This blog explores how modern tower packings, including random packings, can transform columns and why they’re critical for businesses.

Understanding Packed Columns and Their Importance

Think of a packed column as a giant mixing chamber. It’s a tall, cylindrical vessel filled with tower packings that create a surface for liquids and gases to interact. This interaction drives separation or purification in processes like:

- Distillation: Separating liquids by boiling points, like turning crude oil into gasoline.

- Absorption: Capturing gases in liquids, often for emission control.

- Extraction: Isolating compounds from mixtures, vital in pharmaceuticals.

The tower packings, such as Raschig ring column packing, are the heart of the column. They control how well fluids mix, how much energy the process takes, and how long the system runs without issues. Old designs worked years ago, but today’s need for efficiency and sustainability demands smarter random packings and structured solutions. Better packing cuts energy bills, boosts output, and keeps operations smooth.

Why Packing Matters

Tower packings create the surface where liquids and gases meet. The goal is to maximize contact while keeping flow smooth. Good random packings, like Raschig ring column packing, do several key things:

- Increase Contact Area: More surface means better mass transfer, essential for separating substances.

- Guide Flow: They ensure even liquid and gas spread, avoiding channeling, where fluids skip parts of the packing and lower efficiency.

- Cut Energy Use: Less resistance (pressure drop) means less power to move fluids through the column.

- Reduce Clogs: Smart designs prevent solid buildup, keeping the column running longer.

Modern tower packings, especially innovative random packings, take these basics and enhance them with new shapes and materials.

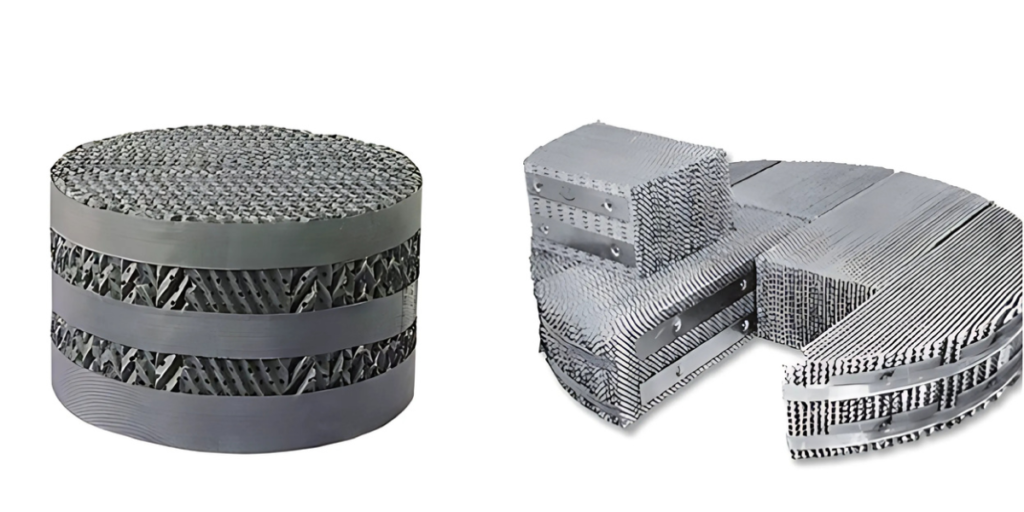

Random vs. Structured Packing: What’s the Difference?

Packing comes in two main types: random and structured. Each has strengths, and choosing the right one depends on the task.

Random Packing

Random packings, like Raschig ring column packing, are small shapes—rings, saddles, or spheres—poured into the column. They’re simple, affordable, and versatile. Common types include:

- Raschig Rings: Basic hollow cylinders, one of the earliest random packings.

- Pall Rings: Improved with holes and internal features for better flow.

- Saddles: Curved shapes that boost surface area and reduce clumping.

Random packings shine in smaller columns or high-liquid-flow processes. They’re easy to install and cost-effective. But if not packed carefully, they can lead to uneven flow. Newer random packings from Varun Engineering use optimized shapes to improve performance without raising costs.

Structured Packing

Structured packing takes a more organized approach, using arranged sheets or grids, often corrugated, to guide fluid flow precisely. It’s ideal for high-stakes jobs like large-scale chemical plants or vacuum distillation. Benefits include:

- Lower Resistance: Fluids move with less pushback, saving energy.

- Higher Efficiency: The orderly design maximizes liquid-gas contact.

- Custom Fit: It can be tailored for specific needs, like handling harsh chemicals or heat.

Structured packings, unlike random packings, come in materials like metal, plastic, or ceramic, depending on the process. For instance, gauze packings suit low liquid loads, while metal sheets handle high-pressure systems.

Why Focus on Column Performance?

Optimizing a column’s performance is about making it work better, not just keeping it running. Here’s why it matters:

- Saves Money: Efficient columns with advanced tower packings use less energy and need less upkeep.

- Boosts Output: Better random packings mean more product processed faster.

- Helps the Planet: Lower energy use and less waste align with green goals.

- Ensures Reliability: Well-designed columns handle tough conditions without failing.

With fierce competition and stricter regulations, outdated random packings won’t cut it. Innovative tower packings keep businesses competitive.

What’s New in Packing Design?

Packing has evolved far beyond basic Raschig ring column packing. Engineers now use cutting-edge tools and ideas to create tower packings that deliver top performance. Here’s what’s driving the change:

1. Smarter Materials

Modern tower packings use materials chosen for strength and performance:

- Metals: Stainless steel or titanium for durability and corrosion resistance.

- Plastics: Lightweight options like polypropylene for less demanding setups.

- Ceramics: Built for high heat or acidic conditions.

- Carbon-Based Materials: Ideal for corrosive chemicals or extreme temperatures.

These materials improve how fluids interact with random packings, like better liquid spread for enhanced contact.

2. 3D Printing for Custom Designs

3D printing is changing the game by enabling complex tower packing shapes. Intricate lattice structures or custom rings maximize surface area while keeping flow smooth. These designs can boost efficiency by 15-20% in some cases, a big win for industries.

3. Computer Modeling

Computational fluid dynamics (CFD) lets engineers simulate fluid movement through random packings or structured designs. This allows testing of tower packings on a computer, tweaking shapes to cut resistance or prevent backups. It’s a game-changer in fields like pharmaceuticals, where precision matters.

4. Hybrid Solutions

Some tower packings combine random and structured benefits. Hybrid gauze packings, for example, offer low resistance with the flexibility of random packings. They’re great for processes like CO2 capture in environmental systems.

5. Fighting Buildup

Clogging, or fouling, is a challenge in columns with sticky or particle-heavy fluids. New tower packing designs use smooth surfaces or wider channels to reduce buildup. For example, structured packings with specific angles minimize spots where solids stick, extending column life.

Key Steps to Optimize Column Performance

Getting a column to perform at its best requires careful planning. Here’s what counts:

1. Picking the Right Packing

The tower packing must fit the job. For distillation, structured packing might excel due to low resistance. For heavy liquid flows, random packings like Raschig ring column packing are often better. Key factors include:

- Fluid Traits: Thickness or stickiness affects how fluids work with tower packings.

- Operating Conditions: High heat or pressure may demand metal or ceramic over plastic.

- Goals: For high-purity output, structured packing often outperforms random packings.

2. Keeping Resistance Low

Pressure drop is the drag fluids face moving through tower packings. Too much drag wastes energy; too little might mean poor mixing. Modern random packings, like corrugated sheets with gentle angles, balance this well. For example, 30°-angle packings often save more energy than steeper ones.

3. Spreading Fluids Evenly

Uneven flow, or maldistribution, hurts efficiency. Liquid distributors at the column’s top ensure fluids spread evenly across tower packings. Advanced distributors prevent shortcuts and dry patches, improving performance by up to 15%.

4. Sizing the Column Right

A column that’s too small can flood, while one too big wastes resources. Metrics like Height Equivalent to a Theoretical Plate (HETP) measure separation efficiency. Modern tools make these calculations precise, ensuring the column fits the job.

5. Staying on Top of Maintenance

Even the best tower packings need regular checks. Monitoring for clogs, pressure spikes, or packing settling catches issues early. Automated systems, like pressure sensors, help adjust conditions before problems grow.

Where Innovative Packing Shines

New tower packing designs are making a difference across industries. Here’s how:

1. Oil and Gas Refining

In refineries, structured packings cut energy use by reducing resistance. With energy often half the operating budget, these tower packings save millions. Some plants see throughput rise by 10-20% with high-performance random packings.

2. Cleaning Up Emissions

Absorption columns use tower packings to trap pollutants like CO2 or sulfur dioxide. Advanced random packings improve capture rates while using less energy, helping meet environmental rules affordably.

3. Drug Manufacturing

Precision is key in pharmaceuticals. Structured tower packings ensure consistent purity in processes like solvent extraction, reducing waste and ensuring safe drugs.

4. Biofuel Production

Separating ethanol from water is energy-heavy. Optimized random packings cut energy use by ensuring even flow, making biofuels more cost-competitive.

Tackling Common Challenges

Innovative tower packings bring big benefits but come with hurdles. Here’s how to handle them:

1. Upfront Costs

Structured packings cost more than random packings like Raschig ring column packing due to complex designs. But energy and maintenance savings often make them worthwhile. A cost-benefit analysis shows the long-term gain.

2. Clogging Issues

Sticky or particle-heavy fluids can clog tower packings. Designs with smooth surfaces or wider channels reduce this risk. Regular cleaning keeps things flowing.

3. Tricky Installation

Structured packings need careful setup to avoid gaps. Training workers and using automated systems ensure a tight, even bed of tower packings.

4. Scaling Up

A design that works in a lab might struggle at full scale. Pilot testing and simulations help ensure tower packings perform in real-world conditions.

What’s Next for Packing Design?

The future of tower packings is full of potential:

- Eco-Friendly Materials: Biodegradable plastics or recycled metals cut environmental impact without losing performance.

- Smart Monitoring: Sensors and AI could track column performance, adjusting flows or flagging issues instantly.

- Algorithm-Driven Designs: Computer-generated tower packing shapes could unlock new efficiency levels.

- 3D Printing Advances: Custom random packings will become more precise and affordable.

These trends will make columns more efficient, sustainable, and adaptable.

Tips for Better Column Performance

For businesses aiming to improve packed columns, here are practical steps:

- Know the Process: Understand needs like output purity or flow rates to pick the right tower packings.

- Invest Smart: High-quality random packings may cost more but pay off in savings.

- Use Simulations: Tools like CFD spot issues before the column is built.

- Train the Team: Proper installation and maintenance are vital for success.

- Keep Monitoring: Regular checks for pressure changes or clogs prevent bigger issues.

Why Varun Engineering Stands Out

Varun Engineering excels in crafting tower packing solutions that deliver results. From high-efficiency random packings to custom structured designs, the focus is on performance, durability, and sustainability. Using advanced tools and materials, the company helps businesses optimize columns while keeping costs and environmental impact low.

Wrapping Up

Packed columns are the backbone of many industries, and their performance hinges on tower packings like Raschig ring column packing or advanced random packings. With innovative designs—new materials, 3D printing, and smart engineering—columns can work harder, use less energy, and last longer. By choosing the right packing, managing flow, and staying on top of maintenance, businesses can save money, boost output, and meet green goals. As technology evolves, tower packings will keep improving, helping industries stay ahead in a fast-moving world.